The PDCA is a cycle that is repeated countless times, and each time this cycle is repeated, it is easier to achieve the established goals through continuous improvement of the production process

This continuous improvement allows the company to better adapt to market changes and customer needs more quickly, always based on concrete data and analyzed in a more rational way.

Although a process can have 80% success rates, a positive number for most areas, the other 20% can mean high material waste rates, high rework rate, among other aspects that damage and cost resources and do not add no value to the final product.

Used in the Toyota Production System, the PDCA focuses on lean production, based on rational management of the production process.

This provides advantages such as:

It's a really great strategy and it can help a lot in a business, making it profitable and easier to manage.

The PDCA Cycle

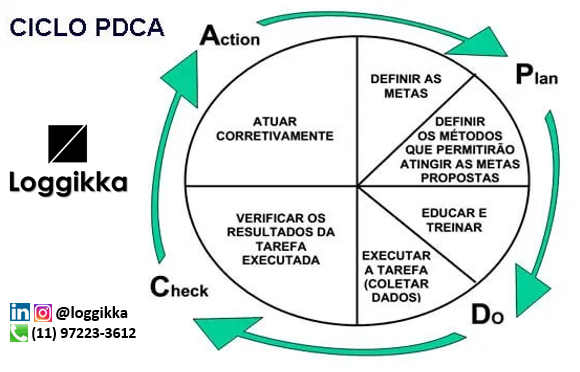

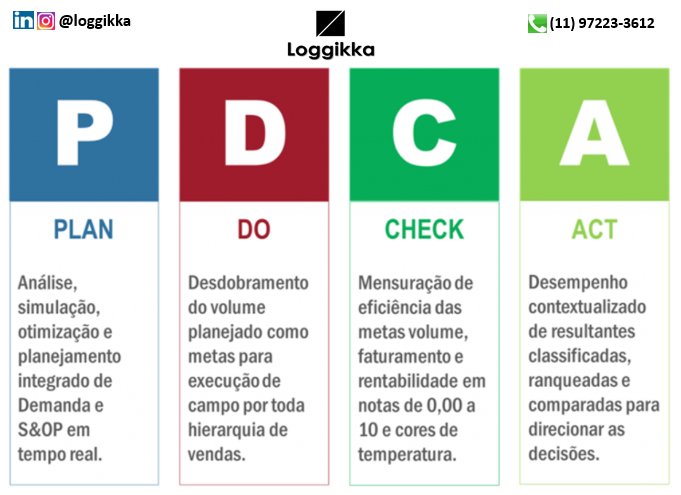

It is essential that companies adopt a strategic posture regarding their positioning, creating goals that will ensure their growth and not their stagnation. One of the best known methods for creating these goals and generating continuous improvement within the industry is the PDCA cycle [Plan, Do, Check, Act). PDCA [Plan (Planejar) – Do (Fazer) – Check (Conferir) – Act (Agir]).

Plan: Establishes the expectations of a company in relation to a certain process. If the company's goal is to reach a 100% success rate in its production, this is the point that the goals have to attack at this stage;

Do: Implement the plan determined in the planning stage. Collect data for mapping and analysis of next steps. Develop target indicators, which are always determined at the exit;

Check: Study the results generated via indicators and numbers. This step depends on other highly measurable steps. Results rate is not measured by employee “feeling”: success lies in developing more effective production control methods, and determining how much more effective they will be;

Act: Corrective measures that go back to the first step of the process. At this point, the initial improvement project no longer exists: it has been improved, adapted and has become a personality apart from what was known as a process in the company.

The main objective of the PDCA Cycle is for it to be really cyclical. Iteration (or repetition) is what guarantees that, at each step, more problems will be solved and that there will, in fact, be an improvement in the process.

PDCA Advantages:

Care to be taken in implementing the PDCA to prevent it from becoming disadvantageous:

.

Do you want to know more about how to apply a good PDCA cycle in your company to reduce raw material waste and improve the Supply Chain?

.

.

Contact us and learn more about continuous improvement and our services!

Loggikka – Innovation in Logistics, Operations and Human Development Whatsapp + 55 (11) 97223-3612 or contact below

Whatsapp (11) 97223-3612 ou no contato abaixo: